Review: The [Specific Brand] Food Dehydrator

Understanding Drying Times

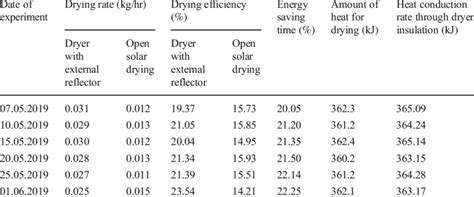

Drying times are a critical aspect of any performance-related process, and understanding the factors influencing them is essential for optimizing results. Accurate drying times directly impact the quality and longevity of the final product. Factors like temperature, humidity, and the type of material being dried all play a significant role in the overall drying process. This detailed understanding allows for efficient resource allocation and ensures consistent product quality throughout the production cycle.

Impact of Temperature on Drying

Temperature significantly affects the rate of evaporation during the drying process. Higher temperatures generally lead to faster drying times, as they increase the kinetic energy of the water molecules, allowing them to escape more readily from the material. However, excessively high temperatures can potentially damage the material, leading to reduced quality and potentially structural changes. Finding the optimal temperature balance is crucial for both speed and preservation of quality.

Humidity's Influence on Drying

Humidity levels in the environment surrounding the drying process play a critical role in the rate of drying. High humidity slows down the drying process, as the moisture in the air competes with the material for drying. Conversely, low humidity accelerates the drying process, allowing water to evaporate more quickly from the material. Understanding and controlling humidity levels is essential for achieving consistent and predictable drying times. Humidity control measures can include the use of dehumidifiers or specialized drying chambers.

Material Properties and Drying Rate

The intrinsic properties of the material being dried significantly influence the drying time. Different materials have varying porosity, density, and moisture content, all of which affect how quickly they absorb and release moisture. Porous materials, for instance, tend to have longer drying times compared to denser materials, because of the larger surface area for moisture to reside. Understanding these material characteristics is crucial for selecting appropriate drying methods and parameters.

Drying Methods and Efficiency

Various methods can be used to accelerate the drying process, ranging from natural air drying to specialized techniques like forced air drying or vacuum drying. Each method has its advantages and disadvantages in terms of drying time, energy consumption, and the potential impact on the material's properties. Implementing appropriate drying methods can significantly reduce drying times and increase overall production efficiency. Choosing the right method involves a careful evaluation of the material being dried, the desired outcome, and available resources.

Comparison to Other Dehydrators: A Fair Assessment

Choosing the Right Dehydrator: Beyond the [Specific Brand] Foo

When evaluating dehydrators, it's crucial to consider a range of factors beyond just one specific model. This involves understanding the differing needs of various users, from casual snack makers to serious food preservation enthusiasts. Different dehydrators cater to diverse needs, from space constraints to specific temperature control requirements. The [Specific Brand] Foo is a worthy contender, but a comprehensive comparison reveals a broader landscape of options.

Capacity and Features: A Crucial Distinction

The capacity of a dehydrator directly impacts its usability. A smaller model might be perfect for a single user or small batch needs, while a larger model is essential for families or those who frequently dehydrate large quantities of produce. Features like adjustable temperature settings, multiple trays, and even integrated timers are key considerations that can significantly affect the overall user experience. Understanding the capacity and features of other dehydrators is vital for a fair comparison.

Temperature Control: A Key to Success

Precise temperature control is paramount for consistent food quality and safety when dehydrating. Variations in temperature can drastically alter the final product, affecting texture, taste, and even nutritional value. Different dehydrators offer varying degrees of precision in temperature control. Exploring other models in the market will reveal a spectrum of options, from basic models to those with advanced digital controls.

Ease of Use and Cleaning: Factors Affecting User Experience

The ease of use and cleaning process significantly impacts the long-term enjoyment of a dehydrator. Intuitive controls, removable trays, and dishwasher-safe components can streamline the entire process. A simple design that minimizes the time and effort required for cleaning is a significant advantage, especially for busy individuals. Comparing dehydrators across different brands and models helps in assessing the practical aspects of the device.

Durability and Construction: Long-Term Value

The construction quality of a dehydrator directly impacts its longevity. Durable materials and sturdy build are crucial for withstanding daily use and ensuring long-term reliability. A well-constructed dehydrator is an investment that can last for years, providing consistent performance without requiring frequent repairs. This aspect should be a consideration when comparing different dehydrators in the market.

Cost-Effectiveness: Balancing Price and Performance

The price of a dehydrator is often a primary concern for consumers. It's essential to weigh the price against the features, capacity, and overall performance. A higher price point may be justified if it comes with advanced features and superior performance, resulting in a better long-term value. Comparing pricing across various dehydrator models is necessary for making an informed decision.

Noise Levels: A Subtle But Important Consideration

While often overlooked, noise levels can significantly impact the user experience, especially if the dehydrator is located in a shared living space. Some dehydrators generate more noise during operation than others. Evaluating the noise levels of different dehydrators is crucial for ensuring a smooth and quiet dehydrating experience. A quiet operating dehydrator can be a significant advantage in a home environment.

Read more about Review: The [Specific Brand] Food Dehydrator

Hot Recommendations

- Traditional Foods for Day of the Dead

- Food Etiquette in Italy: Pasta Rules!

- Best Family Friendly Restaurants with Play Areas in [City]

- Review: The Best [Specific Dessert] Place in [City]

- Top Ice Cream Parlors in [City]

- Traditional Foods for Halloween

- The History of the Potato in Ireland

- Best Vegan Pizza Joints in [City] [2025]

- Best Bakeries for Sourdough Bread in [City]

- Food Culture in Argentina: Asado and Wine

![Review: [Specific Food Stand/Stall Name] Street Food Gem](/static/images/28/2025-05/ValueforMoney3AAStealofaDeal.jpg)

![Review: The [Specific Brand] Digital Meat Thermometer](/static/images/28/2025-05/ValueforMoney3AABalancedAssessment.jpg)

![Review: The [Specific Brand] Bread Maker](/static/images/28/2025-07/BakingPerformance3ATypesofBreads.jpg)